Three steps to GHG-neutrality

The STIHL climate strategy sets out a solid framework for short-term, medium-term and long-term action for climate protection. Because we know that we need a detailed and considered plan to achieve our ambitious goal: For the STIHL Group to one day leave no CO2 footprint worldwide.

We are committed to climate protection and want to be part of defining how it happens. STIHL recognizes the Paris Climate Agreement and acknowledges the target to limit global warming to 1.5°C. With this in mind, in 2020 we set ourselves the long-term goal of operating in a way that is calculable as GHG-neutral. Our guiding principle here is: reducing emissions is more important than carbon offsetting.

In the first instance we will focus on the direct Scope 1 emissions as set out in the Greenhouse Gas Protocol, i.e. emissions from energy consumption that we can control ourselves. At STIHL these are mainly produced by burning natural gas and heating oil for building heating systems, as well as in production, assembly and development. We use fuel in our vehicle fleet and experience coolant losses during operations. We are also looking at our indirect Scope 2 emissions, associated with the purchase of electricity and district heating.

Our locations in Germany have been offsetting their calculated carbon impact for Scope 1 and 2 emissions by acquiring compensation certificates since January 2021. All our international manufacturing companies followed suit in 2022 and the international subsidiaries in 2023.

Long-term climate goals – Scope 3

For greenhouse gas neutrality in Scope 3, we have opted for the 1.5° target according to SBTi and are focusing on the product application phase and supply chain. We are striving to implement greenhouse gas reduction measures for logistics and private transport.

Our path to a positive climate contribution

Achieving the STIHL goal – to positively contribute to climate protection in calculated Scope 1 and 2 emissions – is dependent on the following:

clean eNergy

Since January 2021, STIHL locations in Germany have been exclusively purchasing “green electricity”, which means electricity from renewable sources. Our green electricity meets the strict criteria of the “ok-power” green electricity quality seal, and is 100% sourced from new hydropower plants in Europe. With an average annual electricity consumption in Germany of around 69,000 MWh, purchasing green electricity enables us to immediately reduce our energy-related CO2 emissions in Germany by around 50%.

Almost all STIHL manufacturing companies worldwide have switched to renewable power sources since 2022.

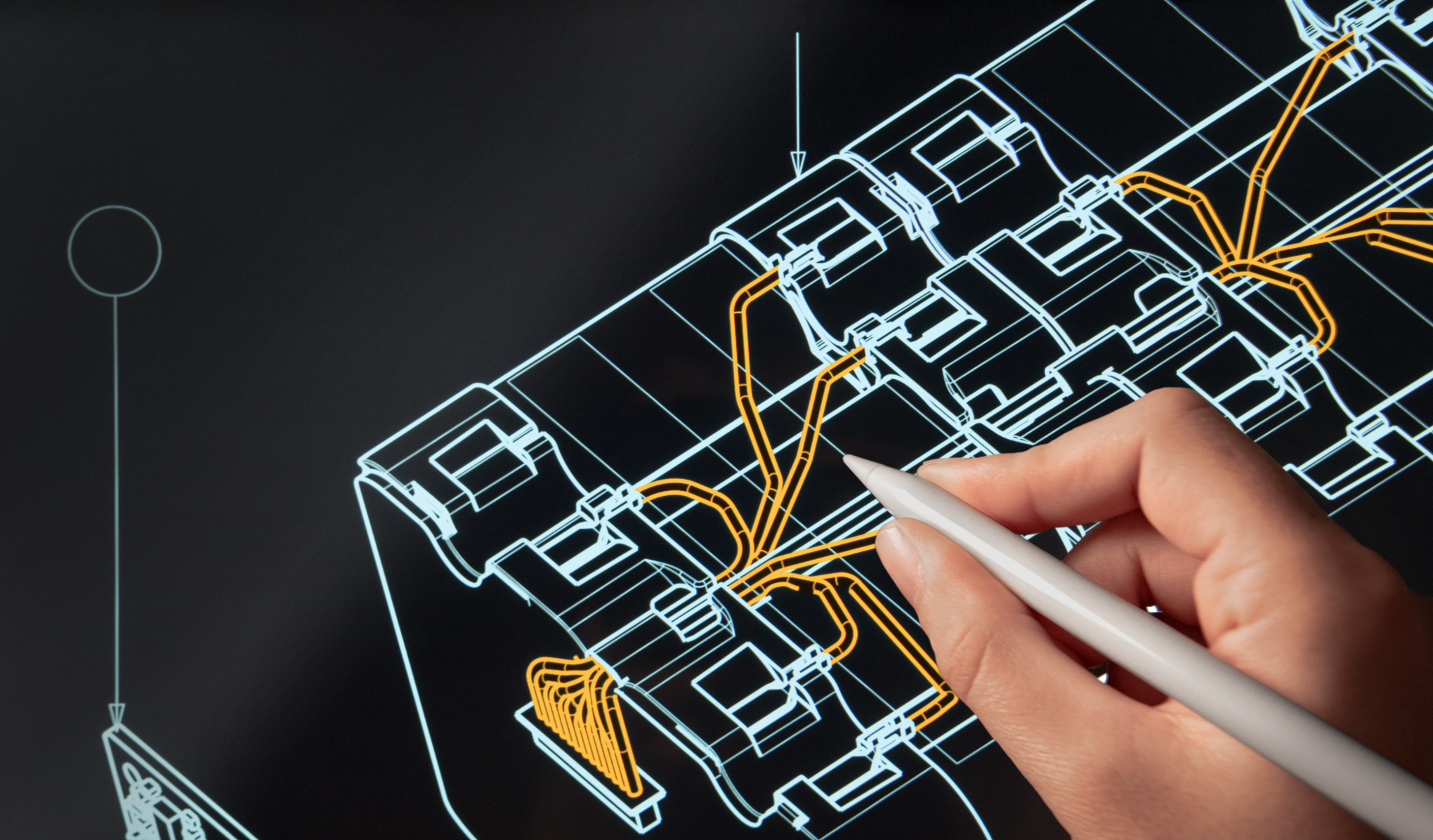

To reduce its environmental footprint, STIHL relies on generating its own electricity using green energy. By using renewable energies such as solar and wind power, we can reduce our dependence on fossil fuels and lower energy costs. A key goal of this strategy is to significantly reduce greenhouse gas emissions.

Decarbonization

By 2030 STIHL intends to reduce its use of fossil fuels by 40% compared with 2019 levels. The primary fossil fuel energy source used at STIHL is natural gas, though other fuels are also consumed. We anticipate that around 80% of the targeted reduction will be achieved through the 100+ individual measures already planned, which include technological innovations such as optimized use of process heat.

Improved energy efficiency

On top of that, we are aiming to reduce our overall energy consumption and so improve our energy intensity. We have long pursued a resource-efficient approach in our manufacturing activities. This is founded on the efficient use of materials, water, electricity, and heat, as well as future-focused building and space planning. Our German plants are certified in accordance with the ISO 14001 environmental management and ISO 50001 energy management standards.

CONTINUOUS IMPROVEMENT IN ENERGY EFFICIENCY

Even with consistently rising production volumes, our implementation of ongoing measures to improve energy efficiency means we have already been able to achieve energy savings in the past. We now intend to intensify our efforts in this area. The focus here is on the implementation of new technologies, such as optimized process heat utilization and distribution, energy storage, improvement and optimization of our energy distribution systems, energy-efficient drive systems for production plants, renewable energy generation, and energy-saving lighting.